There are many different types of insulation to use in your home’s walls, attic, and basement, but the two most common types of insulation are fiberglass and cellulose. They share some similarities and have differences, and the application will generally dictate which substance you will use.

Cellulose Insulation, Advantages and Disadvantages:

Advantages:

- Made of paper, cellulose helps reduce paper waste through recycling the material for insulation

- Treated with boric acid helps the material become flame retardant, rejects mold spores, and stops insects from invading

- In some cases, cellulose is treated with an acrylic binder that prevents R-value degradation over time

- Costs are cheaper with cellulose insulation, in some cases 25 per cent cheaper

- Has a higher R-value per inch in comparison with fiberglass (R-3.2 – R-2.2 per inch)

- It is less of a health hazard than fiberglass

Disadvantages:

- Installation costs are higher for cellulose

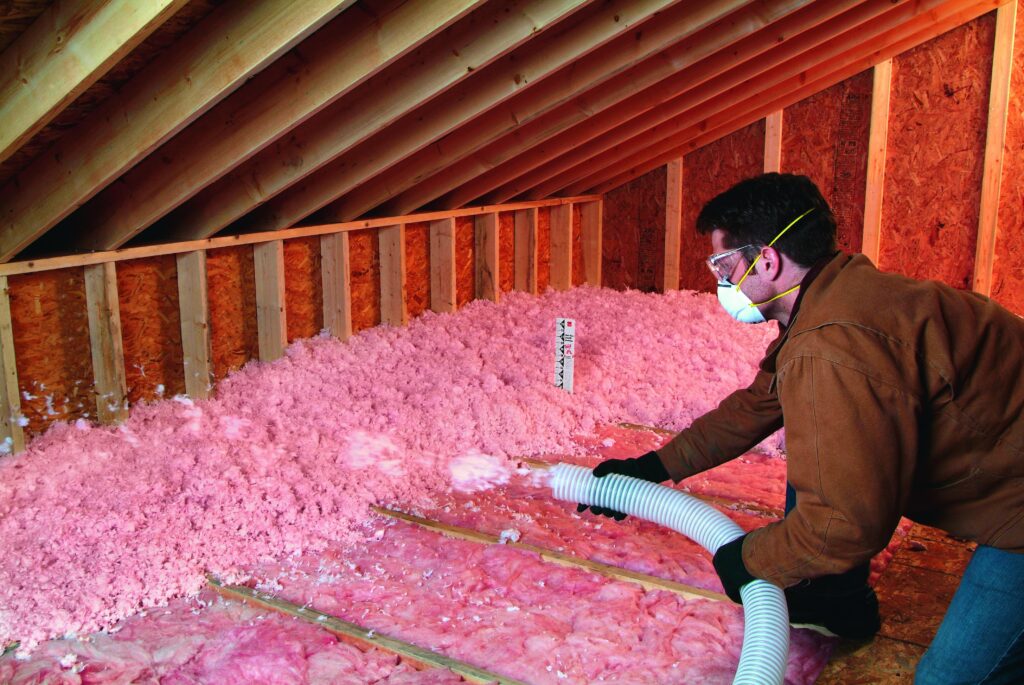

- Creates a massive cloud of dust when installed, and breathing apparatus may be necessary for large installations.

- Dry-blown cellulose characteristically settles and sags in place, and that reduces its R-value.

- As a recycled paper product, cellulose is prone to absorbing moisture, which can cause mold and wood rot. Additionally, wet-blown cellulose is also susceptible to similar contamination.

Fiberglass, Advantages and Disadvantages:

Advantages:

- Fiberglass insulation is very effective as an insulator and is inexpensive on the pocketbook

- Fiberglass insulation does not shrink over time

- Insulation manufacturers supply the material in sealed batts that are wrapped in a plastic film to prevent health risks

- The plastic film that the batts are wrapped in acts as a vapour barrier

- Fiberglass insulation is 100 per cent flame retardant and will not burn

- Most fiberglass insulation is made with recycled materials, and that reduces its carbon footprint

- Fiberglass insulation comes in two types of density – medium and high – and that translates into an R-11 and R-1.5, respectively, for a standard 2×4 wall

- Fiberglass insulation has no nutritional value for insects, so they will leave it alone

Disadvantages:

- Personal protective equipment must be worn when working with fibreglass, as the slivers of insulation can be inhaled and get stuck on the skin

- If you do not use sealed batts, fiberglass insulation will require a vapour barrier during the installation phase

- Blankets of fiberglass have trouble sealing walls and ceiling spaces well

- Fibreglass insulation, over time, will sag and settle, reducing its R-value

Both cellulose and fiberglass are the two most inexpensive insulation products available, and fiberglass is the most common product for insulation, outpacing cellulose by a ratio of 50:1. Both share common characteristics. Both are in direct competition for the residential insulation market, offering distinct options when deciding on the type of product to use.

Fiberglass insulation is the easiest insulation product on the market to install, and when installed correctly, it is the most effective product available for home attic insulation. When using cellulose–blown–in dry insulation, it requires a machine to achieve its purpose and a training session from the source from which you rent the blower.

Both products have similar R-values per inch, but they can vary due to the circumstances that affect your home. Insulation settling can be a problem, as temperatures and wind washing are common issues that affect the insulation’s ability to retain heat in the house.

Both types of insulation require an air barrier to be installed at the time the insulation is added. Fiberglass is susceptible to air leakage, which can affect the R-value of the installed product. Both products can absorb moisture, and each has the capacity to dry quickly; however, in a damp environment like a basement, this can be problematic.

As mentioned previously, both products react differently to flame and fire. If fiberglass insulation is exposed to flame and fire, it will melt as it is made up of glass fibres. The problem, though, is the wrapping that comes with batts; it is flammable and could ignite if exposed to open flame. As for cellulose, it is heavily treated with chemicals to reduce its flammability. While the substances may not be harmful to humans, they are highly effective in their intended use.

When selecting a product for your insulation needs, always consult a professional for their advice, as each product is suited to different applications and no two applications are alike. Additionally, consider the weather in your area and your lifestyle to make the decision easier.